History and evolution

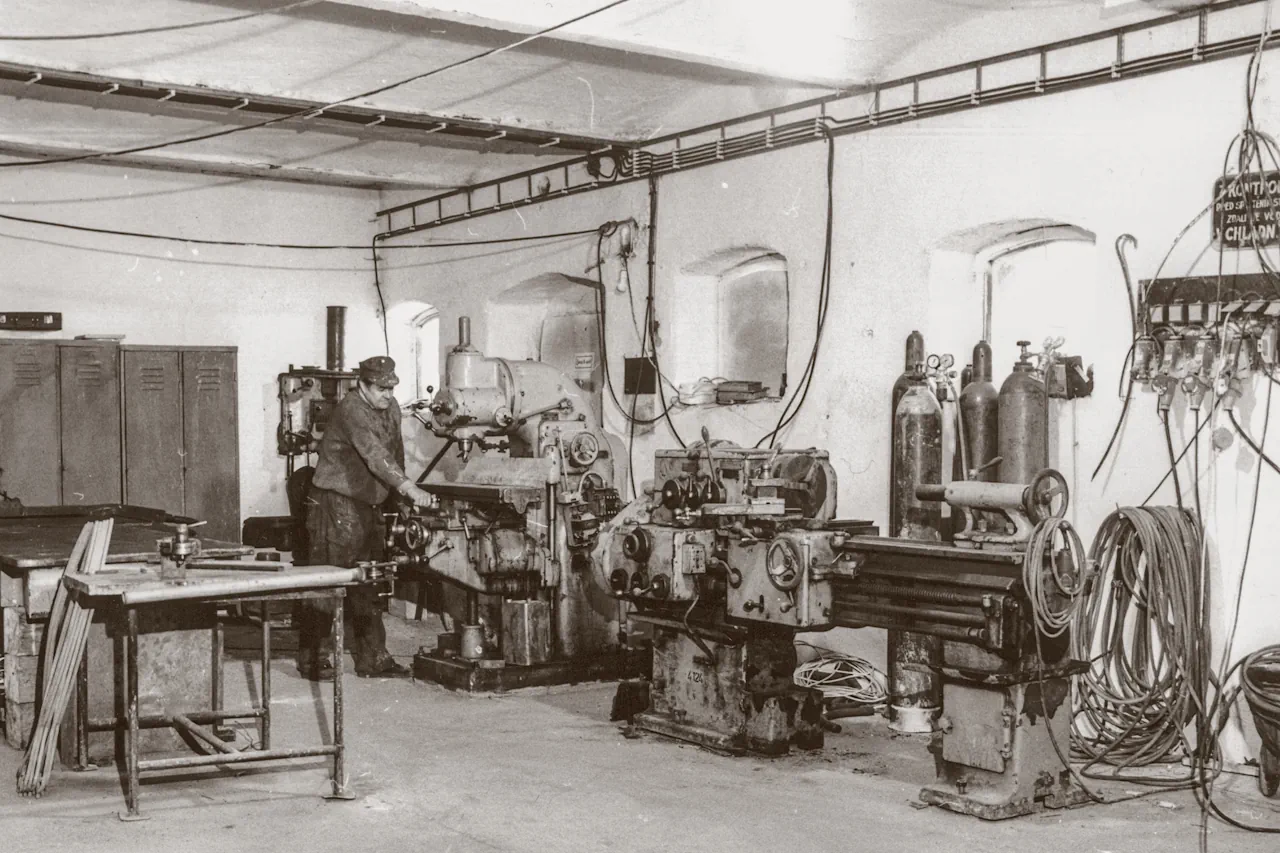

The company, originally named Stroj & Spol., was founded by Mr. Josef Baumruk in 1990. With three permanent employees initially, it focused on custom metal fabrication, especially on the design and production of custom structures. In 1994, it acquired new premises, and after their reconstruction, it significantly expanded.

The company quickly acquired new customers, production expanded, and this small family business gradually needed to transition to conventional financing methods. As an organizational change, in 1996, the company BAUMRUK & BAUMRUK s.r.o. was established, which, over its existence, underwent a number of improvements and gained a leading position, even beyond borders.

Several key events in the company's development

1997

The arrival of foreign customers and the expansion into a new area

The precision of work and the fulfillment of all agreements attracted foreign customers and with them, serial production of various metal components for construction machinery. In 1997, the owners purchased the business shares of Yamas s.r.o. and expanded the existing premises with a production facility in Chrást near Plzeň. This allowed for increased production capacities and the start of trading spare parts for railway vehicles.

2000

Supplier qualification certificate and new hall

In 2000, a quality system according to ČSN EN ISO 9001:2001 was implemented, and the company became the holder of the 'Certificate of Technical Eligibility for Suppliers of Czech Railways a.s.' In 2002, production capacities were expanded with a workshop enabling higher production autonomy in the production of spare parts and components for railway vehicles. Two years later, the construction of a new hall in Chrást near Plzeň was completed, where production capacities were relocated.

2006 a 2010

Investments in automation and ERP system

In 2006, the second generation of the Baumruk family took over the management of the company, and from 2007 onwards, the company significantly invested in automation, machinery, and software equipment. The machinery park was completely renewed within one year. Obtaining certifications in the field of welding ČSN EN ISO 3834-2 and ČSN EN 15085 allowed for further success in a tough competitive environment. In 2010, a new ERP system was implemented, which streamlined all company processes and enabled EDI communication with key customers.

2013

Renovation of the production area and construction of new halls

In 2013, the company made significant investments in further development. The entire production area underwent a complete renovation. A new modern production hall with an area of 3,200 m² and two storage halls with a total area of 1,000 m² were built. The construction also included a new administrative building and social facilities with a usable area of 700 m². At the same time, investments were made in machinery equipment, including the installation of a new powder coating facility.

2015 až 2017

Equipment with new laser centers, new halls, land and investment in development

In the years 2015-2016, further investments were made. In addition to expanding machinery equipment (especially the acquisition of 2 laser cutting centers, CNC bending center for pipes, etc.), a new dispatch hall with an area of 660 m² was built. Furthermore, adjacent land with an area of 22,700 m² was purchased, allowing for future company development.

In 2017, a new welding shop with an area of 2,000 m² and a warehouse of 600 m² were built. There was a significant strengthening of automation through new welding robots along with the use of offline programming. Investments were also made in warehouse automation, CNC machining, and measuring technologies.

2018 až 2022

New technologies in production

Between 2018 and 2022, production was enhanced with new technologies. Among the most significant were 2 laser cutting centers, 2 bending presses, 2 five-axis machining centers, and several CNC turning centers equipped with loading robots. The company also invested in machinery for processing stainless steel for the healthcare industry, including the acquisition of a TIG welding robot and a stainless steel nozzle.

A significant technological advancement occurred in 2022 when another production hall with an area of 3400 m² was completed. The main reason for the construction was the need for space for a new automated powder coating facility with 2 painting robots and chemical pretreatment. As part of the plant's modernization, several new machining machines and welding robots were purchased. There was also an optimization of the entire logistics flow.

2023

Investments in renewable energy sources and installation of a photovoltaic power plant

In 2023, the company invested in renewable energy sources. In addition to expanding heating with the option of biomass combustion, a 650 kWp photovoltaic power plant and a 614 kWh battery storage were installed.

In 2023, the company employs over 100 skilled full-time employees, operates modern production and administrative facilities with a total area of nearly 13,400 m², and is capable of offering customers first-class service.

2024 až 2025

Strengthening of production, new machining equipment, and a 5,000 m² facility expansion

Between 2024 and 2025, the machining was significantly strengthened — two high-performance four- and five-axis machining centers, Matsuura MAM72 and H630, equipped with pallet exchange systems, were acquired. We also installed a MEWAG Telarus 170, one of the most powerful tube bending machines in Europe.

In 2025, the company purchased an adjacent production facility with an area of 5,000 m², enabling future expansion.

As of 2025, the company employs 120 qualified full-time staff, operates modern production and administrative facilities with a total area of nearly 13,400 m², and is capable of offering customers first-class service.

Contact us

We welcome each of your inquiries and comments. You can easily connect with us and obtain the necessary information.